What is Metal Casting?

Metal casting is defined as the process in which molten metal is poured into a mould that contains a hollow cavity of a desired geometrical shape and allowed to cool down to form a solidified part. The term ‘casting’ is also used to describe the part made by the casting process which dates back 6000 years. Historically it is used to make complex and/or large parts, which would have been difficult or expensive to manufacture using other manufacturing processes.

Primarily, casting produces ingots and shapes. An ingot is a casting produced into a simple shape and intended for further processing such as metal extrusion, forging, etc. Shape casting is for near or net shape castings to produce complex geometries which are closer to the final part.

Types of Metal Casting

Metal casting can be divided into two groups by the basic nature of the mould design. i.e. expendable mould and permanent mould castings. It can be further subdivided into groups depending on their pattern material.

● Expendable Mould

● Permanent pattern

● Sand casting

● Plaster moulding

● Shell mould

● Ceramic mould

● Expendable pattern

● Lost foam

● Investment casting

● Permanent mould

● Gravity casting

● Low pressure/vacuum

● Die casting

The following factors need to be considered before choosing a suitable metal casting for a given engineering product design.

● Part shape and size

● Required quantity

● Required tolerance

● Material

Expendable mould casting

Expendable mould casting, as the name suggests uses a temporary non-reusable mould to produce the final casting as the mould will be broken to get the casting out. These moulds are typically made of materials such as sand, ceramics & plaster. These are generally bonded using binders called bonding agents to improve their properties. Complex intricate geometries can be cast using expendable mould casting.

Permanent mould casting

Sometimes called non-expendable mould casting, permanent mould casting uses permanent moulds that are reused after each production cycle. Although permanent mould casting produces repeatable parts due to re-use of the same mould, it can only produce simple castings as the mould needs to be opened to remove the castings.

Composite mould casting

As the name suggests these uses both expendable and re-useable casting moulds to produce castings. These normally include materials such as sand, wood, graphite and metal.

How does metal casting work?

Metal casting steps

1. Patternmaking – A replica of the part to be cast is made using a suitable material such as wood, metal plastic or plaster.

2. Mould making – Mould making is a multi-step process in which patterns and cores are used to create a mould. The type and how the moulds are made would vary depending on the type of metal casting. For example, sand casting uses sand inside a flask to create moulds and die casting uses hardened tool steel moulds.3. Metal melting & pouring – Liquid is then melted and poured into the mould cavity either by gravity or by high pressure. Then the cast is allowed to solidify before the cast parts are removed from the mould. Again, the cast part removal will vary depending on the type of metal casting.

4. Post-processing – In this final step, the cast metal object is removed from the mould and then fettled. During the fettling, the object is cleaned of any moulding material, and rough edges are removed.

Elements of the gating system

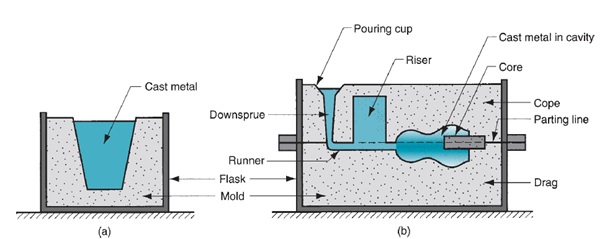

One of the most common metal casting processes is Sand casting and its mould is made of two halves. Contained inside a box called a flask, the upper half is called the cope and the bottom half is called the drag. As shown in the image below the flask is also divided into two halves. The line that separates the two halves is called the parting line.

The gating system is the channel or the path by which the molten metal flows into the cavity. As shown above, the gating system consists of a pouring cup and a down sprue through which the metal enters the runner that leads into the main cavity. Pouring cup minimises the splash and turbulence when the metal flows through the sprue which is tapered to aid the flow. Most of the casting suffers from shrinkage during cooling and to minimise the shrinkage issue, a riser is used. A riser is a simple reservoir in the mould that feeds molten material to the shrinking sections to compensate as it solidifies. There are four different types of risers, viz. top riser, side riser, blind riser and open riser.

Material suitability

Although almost all the metals can be used, the most common ones are iron, steel, aluminium, magnesium and copper-based alloys such as bronze.

Zinc, aluminium, magnesium and brass are widely used in die casting whereas aluminium alloy, brass alloy, cast iron and cast steel are very popular sand-casting materials.

Typical application

Nearly every engineering product we use from washing machines to pillar drills, cars to bicycles is manufactured using metal parts which are most likely to be made using one of the metal casting processes. This age-old manufacturing process has improved its precision and tolerances over time.

Typically, castings are used to make car engine blocks, crankshafts, power tool housings such as pillar drills, plumbing parts, turbine blades, metal statues, some gears and gearbox housings.

Advantages and disadvantages of metal casting

As with any other manufacturing process, a basic understanding of the process, its underlying science, its pros and cons are essential for manufacturing low-cost quality engineer products.

Advantages of metal casting

● Features like internal cavities or hollow sections can be easily achieved

● Large components can be produced in one-piece cast

● Materials that are difficult or expensive to manufacture using other manufacturing processes can be cast

● Compared to other manufacturing processes, casting is cheaper for medium to large quantities

● Almost all the metals can be cast

● Near net shape often without or very minor post-processing

Because of the above reasons metal casting is one of the important net shape manufacturing technologies. Others include net shape forging, stamping of sheet metal, additive manufacturing and metal injection moulding.

Disadvantages of metal casting

● Relatively coarse surface finish and hence wider tolerance has to be allowed and not suitable for mating interfaces

● Metal casting such as shell moulding has a limit in terms of size and the pattern● Patterns are time-consuming and expensive to make although additive manufacturing processes such as binder jetting are being used lately to make a mould

● Die casting can be very expensive for smaller to medium quantities due to the high die cost

● Part size and material choices depend on the casting process chosen. For instance, only non-ferrous metal can be used for permanent mould castings.

ABOUT KEVA

Keva Casting is a professional casting company that focuses on Construction, Machinery, Automobile, Hardware, Pipeline and many other industries.

We provide top quality products with the best service based on our complete production chain including our own mold design, advanced production techniques, and full management of the supply chain. Keva Casting has two factories located in Zhucheng, China's Shandong province.

We use "shell molding", which is a new technique that has been developed in recent years.This new technique has simplified production procedures and reduced air pollution compared with traditional sand casting and investment casting. Shell making and core making are faster to ensure production in enormous quantities. The dimensions and surface finishing are satisfactory for all kinds of industrial requirements. Besides supplying our own formwork & scaffolding systems, our casting products also supply OEM services in various industries.